What are the characteristics of good paraffin?

The difference between solid paraffin and liquid paraffin

January 24, 2023What are the characteristics of good paraffin?

Paraffin oil was discovered in the 19th century, when Carl Von’s petrochemical industry was trying to refine oily compounds and increase efficiency. What are the characteristics of good paraffin and what are the types of paraffin?

First, we will discuss the history of paraffin and then we will learn about the types and characteristics of paraffin, and we will describe the production process of industrial paraffin, chloratus paraffin, microcrystalline or heavy solid paraffin, and the manner of distinguishing high-quality paraffin from low-quality paraffin. Paraffin has two types, solid and liquid, each of which has different uses and properties, which will be explained as follows.

Paraffin is one of the most important materials that plays a significant role in the industry and its usage is increasing every day. This applicable material was first discovered by a German scientist, named Carl Ludwig von Reichenbach, who was born on February 12, 1788 in Germany.

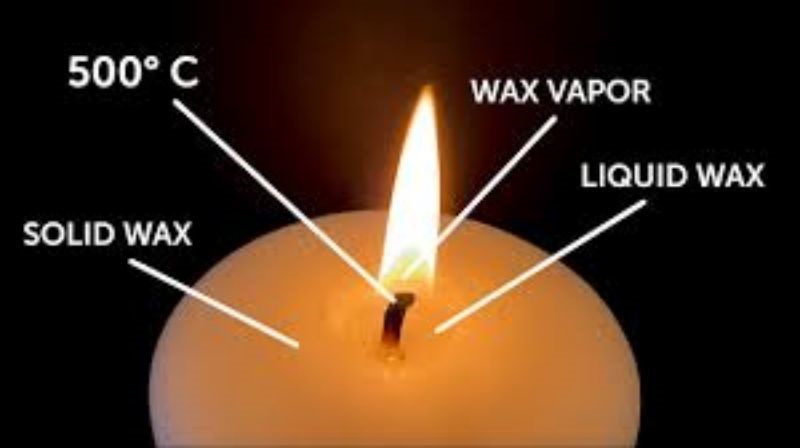

Whereas paraffin burns cleaner and safer than other common oils in candle making, increasing in using this material became an important factor. Among the most important uses of paraffin in the early 20th century, we can mention the candle making, meat packing and oil production industries.

Paraffin is available in two types of liquid and solid in the market. Paraffin is sometimes found in jelly form, that its solid and jelly forms are used for making all kinds of candles, and its liquid form is used for industrial purposes.

Paraffin oil was discovered in the 19th century, when Carl Von’s petrochemical industry was trying to refine oily compounds and increase efficiency. What are the characteristics of good paraffin and what are the types of paraffin?

First, we will discuss the history of paraffin and then we will learn about the types and characteristics of paraffin, and we will describe the production process of industrial paraffin, chloratus paraffin, microcrystalline or heavy solid paraffin, and the manner of distinguishing high-quality paraffin from low-quality paraffin. Paraffin has two types, solid and liquid, each of which has different uses and properties, which will be explained as follows.

Paraffin is one of the most important materials that plays a significant role in the industry and its usage is increasing every day. This applicable material was first discovered by a German scientist, named Carl Ludwig von Reichenbach, who was born on February 12, 1788 in Germany.

Whereas paraffin burns cleaner and safer than other common oils in candle making, increasing in using this material became an important factor. Among the most important uses of paraffin in the early 20th century, we can mention the candle making, meat packing and oil production industries.

Paraffin is available in two types of liquid and solid in the market. Paraffin is sometimes found in jelly form, that its solid and jelly forms are used for making all kinds of candles, and its liquid form is used for industrial purposes.

Using paraffin to make candles

Paraffin is actually a petroleum substance that can be found in both liquid and solid forms in the market. Jelly and solid paraffin (paraffin wax) have long been used more than anything else in candle making.

Another characteristic of paraffin is that paraffins have different melting points, for example, the paraffin needed to make casting candles must have a melting point of 60 to 63° C.

The quality of paraffin for making candles

You can usually find only three types of paraffin for making candles in stores.

1- Formed paraffin (acid) is mostly used in making old candles.

2- Crystalline paraffin (without acid) used for making handmade candles due to its greater flexibility.

3- Glass or medical paraffin is suitable for producing candles made in glasses and containers because this type of paraffin is for the production of decorative candles and is oily and completely paraffin-like. It is slippery and loose. Candles are generally divided into the following two categories:

Candle

Handmade candles

The difference between paraffin and natural waxes

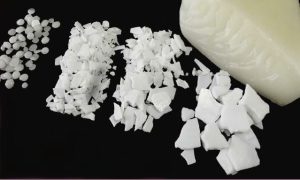

Paraffin wax is lighter in color than crude oil and is odorless and has different melting points. The supply of paraffin wax is made from inside and outside the country. Paraffin wax is packaged in bulk, slabs and pastilles, which are used in various applications.

Some important points about specifications of paraffin:

- Stearic acid (stearin): Stearic acid (stearic) should be added to paraffin to help harden the paraffin. This material increases the burning time of the candle. To see the burning time of different types of candles, you can refer to the page of candle price.

- Candles which are prepared in a mold, contain 2 to 5 teaspoons of stearic acid for 454 gr. of paraffin (actually 100 gr. are needed for every 1 kilogram of paraffin)

- The quality of paraffin can be recognized by its color, another characteristic of paraffin is its color quality. So, the whiter and clearer the color of paraffin, the higher its quality.

It is worth mentioning that one of the other characteristics of paraffin is that the main use of this product is candle making, foodstuff, leather, and etc. Solid kerosene is widely exported to Central Asian countries and African countries.

Distinguishing high-quality paraffin from low-quality paraffin

We can say much for determining the quality and specification of paraffin. High-quality paraffin has a light color. Dark color does not mean a high percentage of fat. Paraffin colors can be made clearer and brighter with filters.

The best choice is a low-fat paraffin board, which looks like a wooden board but does not crack when dropped on the floor. The paraffin board should show countless crystal grains when exposed to sunlight. Also, paraffin should not be soap.

It is a bit difficult to determine the purity of paraffin granules, but the best way is to melt some paraffin granules first and then cool it completely in the mold, and then perform the above operation for determining.

Crystalline paraffin

The main component of this type of paraffin is slack wax and it is obtained from sweated paraffin. Another characteristic of solid paraffin is that solid paraffin is less known as crystalline paraffin in the market. Paraffin crystals can have different percentages of oil based on the needs of the consumer.

Slack wax is a composite material made of wax and petroleum, which is a byproduct of engine oil factories and a key ingredient in producing paraffin. This product is derived from Lubcat, a byproduct of the engine oil production process.

In the process of paraffin extraction, flat wax is entered into the production system as a feed and it becomes the final product after performing important processes such as resuscitation and coloring. This product is called paraffin wax. The oil obtained at this step, becomes Fots Oil or residual wax, which is used for industrial purposes.

Microcrystalline or heavy solid paraffin

More than 90% of solid paraffin available in the market are heavy and micro types, which can have different percentages of oil based on the orders of reliable customers. This type of paraffin is heavy silica wax obtained from pressing steel plates on packed silica wax at a certain temperature.

Producing Process of Industrial Paraffin

The producing process of industrial paraffin can be one of the following methods:

1- Acidic process: In this method, impure paraffin is separated from the center, after re-melting the plastic wax and adding cold solvent acid. After this process, the product is dried and purified with sulfuric acid. Final cleaning removes contaminants through the soil and the residue is finally removed after filtration.

2- Sweating process: In this process, it continues with hot oil and sulfuric acid cleaning, shortly after the first production and then the work continues with the same acid process (from the washing part).

Chlorates Paraffin

Chlorates paraffin refers to the hazards of valuable chemicals used in the polymer industry, especially plasticizers in PVC, flame retardants for plastics and rubbers, anti-paint loss agents for paints and additives, and high pressure engine oils. (additives) are widely used and thousands of tons of these materials are produced and consumed annually.

52% chlorinated paraffin is widely used as a cleaning agent or in the cable industry, synthetic leather, flooring and etc. in the country.