What is Paraffin?

July 30, 2022

Cycloparaffin or Naphthenes

July 30, 2022

Paraffin

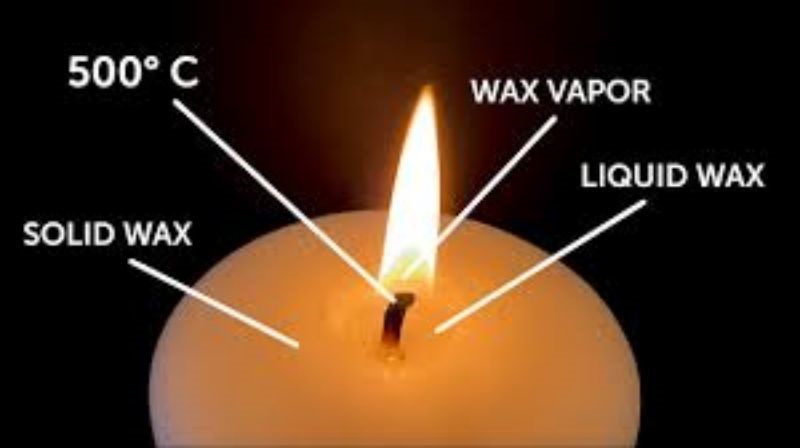

Paraffin is applied to a lot of things we use in our daily lives. We used them for protecting fruits, dyeing, paper, wood and textile industries, foundry industries, producing colored polymers, colored plastics and rubbers, printer inks and waterproof paints for building.

For producing these paraffin, first monocrystalline paraffin was produced with the help of oily wax and then colored paraffin was produced with the help of different pigments, which are generally parts of Azo-pigment family. In this project an oil-free paraffin sample was produced by distillation of oily wax and the physical properties thereof were studied. Then the pigments, suitable for coloring the mentioned paraffin, were selected and used. Different tests have been performed after coloring for optimizing the properties of colored paraffin including temperature, stirring and color concentration. Different solvents have been tested in the formulation of colored paraffin too and finally the best method for producing colored paraffin was selected and discussed.